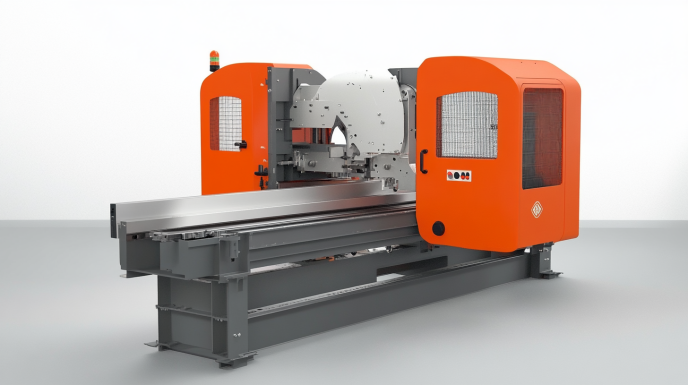

BAUER 10 Amp Deep Cut Variable-Speed Band Saw

- Powerful 10 amp motor maintains cut speed through the toughest materials

- Extra-large 5 in. x 5 in. deep-cut capacity

- Variable-speed control dial provides flexibility to adjust for different applications

- Lightweight design minimizes user fatigue

Unleashing Precision and Power in Your Workshop

There’s something deeply satisfying about the perfect cut. That clean edge, the precise angle, the smooth finish that tells you you’ve done the job right. As someone who has spent countless hours in workshops both professional and makeshift, I’ve come to appreciate tools that deliver consistent results without breaking the bank. Today, I want to dive deep into one such tool that has been making waves in the DIY and professional communities alike: the Bauer band saw.

Whether you’re a seasoned woodworker looking to upgrade your arsenal or a weekend warrior just starting to build your collection, understanding the capabilities and limitations of your tools is crucial. So grab your safety glasses and let’s cut through the noise to explore everything you need to know about this versatile workshop companion.

What Exactly Is a Bauer Band Saw?

At its core, a band saw is a power tool that uses a continuous band of toothed metal stretched between two or more wheels to cut various materials. What sets the Bauer band saw apart is its careful balance of affordability, durability, and performance.

The Bauer brand is exclusive to Harbor Freight Tools, a company that has been steadily improving its reputation by offering surprisingly capable tools at accessible price points. The Bauer line represents their mid-tier offering—tools designed to bridge the gap between basic DIY equipment and professional-grade machinery.

The Bauer band saw comes in several configurations, but their standard 10-inch model has become particularly popular among hobbyists and professionals on a budget. It’s a corded electric tool featuring a robust motor that drives a continuous metal blade through various materials with impressive precision.

What initially drew me to this particular saw was its compact footprint compared to other models I’d used. Don’t let the size fool you, though—this tool packs a serious punch where it counts.

The Investment: How Much Will a Bauer Band Saw Set You Back?

Let’s talk numbers, because budget considerations are often the deciding factor when adding to your workshop collection.

The Bauer band saw typically retails between $129.99 and $149.99 for the standard model—significantly more affordable than comparable brands that can run $200-300 for similar specifications. During Harbor Freight’s frequent sales events, you might snag one for even less, sometimes dropping below $120 with coupons or special promotions.

This price point is particularly impressive considering the features packed into the machine. While it won’t match the capabilities of industrial saws costing thousands, it offers tremendous value for small to medium projects. I’ve found that many tools in this price range make significant compromises, but the Bauer manages to maintain essential features while keeping costs reasonable.

Remember that the initial purchase is just part of your investment. Factor in replacement blades (typically $10-20 each, depending on type and quality) and any accessories you might want to add. Even with these additions, you’re looking at a total investment that won’t break the bank.

Where to Purchase Your Bauer Band Saw

Since Bauer is a Harbor Freight exclusive brand, your purchasing options are straightforward. You can buy directly from any Harbor Freight retail location—they have over 1,100 stores across the United States—or through their official website.

I recommend visiting a physical store if possible. There’s something valuable about seeing the tool in person, assessing its build quality, and speaking with staff who might offer insights based on other customers’ experiences. Most Harbor Freight locations have floor models available, allowing you to get a feel for the size, weight, and overall construction.

If online shopping is more your style, Harbor Freight’s website offers detailed specifications and occasionally web-exclusive deals. They frequently offer free shipping on orders over a certain amount, which the Bauer band saw typically qualifies for.

One thing to note: unlike many other tool brands, you won’t find new Bauer tools on Amazon or at other retailers like Home Depot or Lowe’s. However, you might occasionally spot used models on marketplace sites like eBay or Facebook Marketplace if you’re hunting for an even better deal.

Power Source: Corded Reliability

In an age where cordless tools are increasingly popular, the Bauer band saw has remained firmly in the corded camp—and for good reason. This tool requires consistent, uninterrupted power delivery to maintain blade speed and cutting performance, particularly when working through tougher materials.

The standard model features a 10-amp motor that plugs into any standard 120V outlet. This might seem like a limitation in today’s battery-powered world, but I’ve found it to be a strength for stationary workshop tools. There’s no battery to run down mid-project, no charging to monitor, and no gradual loss of power as the charge depletes.

That said, the corded design does mean you’ll need to plan your workspace around outlet accessibility. I’ve set up my workshop with strategically placed power strips to accommodate this and other corded tools. For those who absolutely need portability, extension cords are always an option, though I’d recommend heavy-duty 12 or 14-gauge cords for tools of this power rating.

Versatility: What Materials Can the Bauer Band Saw Handle?

One of the most impressive aspects of the Bauer band saw is its material versatility. With the right blade installed, this tool can effectively cut:

- Softwoods and hardwoods up to several inches thick

- Plywood and other sheet goods

- Plastic and acrylic sheets

- Non-ferrous metals like aluminum

- Thin-gauge steel and other ferrous metals (with appropriate blades)

- PVC and other pipe materials

- Some laminate materials

This versatility makes it an excellent all-around tool for diverse projects. I’ve used mine for everything from creating curved furniture components to cutting custom brackets from aluminum stock.

The key to successfully cutting different materials lies in selecting the appropriate blade and adjusting your cutting speed. For woodworking, general-purpose blades with 6-10 teeth per inch (TPI) provide a good balance of cutting speed and finish quality. When working with metals, you’ll want to switch to a blade with 14-24 TPI and reduce your cutting speed.

I’ve found that the Bauer handles wood exceptionally well—smooth, consistent cuts with minimal blade wandering. Metal cutting is serviceable, though not as impressive as with dedicated metal-cutting band saws. Still, for occasional metal work, it performs admirably with the right setup.

Cutting Capacity: How Big Can You Go?

Understanding a band saw’s cutting capacity helps determine the scope of projects it can handle. The Bauer band saw offers a respectable throat capacity of approximately 9-3/4 inches, referring to the distance between the blade and the vertical frame of the saw. This measurement determines the maximum width of material you can cut.

For height, the standard model accommodates materials up to about 6 inches tall under the guide bearings. These dimensions place it firmly in the mid-range category—suitable for most furniture components, small crafts, and medium-sized projects.

To put this in practical terms, you could comfortably cut:

- Curved components for chairs and small tables

- Decorative brackets and architectural elements

- Custom boxes and storage solutions

- Instrument parts like guitar bodies

- Detailed scrollwork for decorative pieces

Where you might find limitations:

- Very large furniture components like full table tops

- Wide boards beyond the throat capacity

- Extremely thick hardwoods (though multiple passes can sometimes overcome this)

I’ve found these limitations rarely problematic for my work. When I do need to cut larger pieces, I typically use a circular saw or table saw for rough cutting, then refine with the band saw if necessary.

Comparative Analysis: Bauer vs. Other Brand Band Saws

To truly understand the Bauer band saw’s value proposition, we need to see how it stacks up against competitors. I’ve had the opportunity to work with several different brands over the years, and the comparisons are illuminating.

Bauer vs. WEN

WEN offers band saws in a similar price bracket (around $160-200), and their build quality is comparable. In my experience, the Bauer edges out WEN slightly in power delivery and stability, though WEN often includes more accessories out of the box.

Bauer vs. DEWALT

DEWALT band saws, generally priced in the $300-400 range, offer superior build quality and longer-lasting components. However, the performance difference doesn’t necessarily justify the significant price increase for many hobbyists. The Bauer delivers about 80% of the performance at roughly 40% of the cost.

Bauer vs. Milwaukee

Milwaukee’s premium band saws ($400+) feature enhanced durability and professional-grade components. They’re engineered for daily use in commercial settings. While noticeably superior in build quality, the substantial price difference makes the Bauer a compelling alternative for those who don’t need industrial-level durability.

Bauer vs. Ryobi

Ryobi’s entry-level band saws (around $150-200) compete directly with the Bauer. In side-by-side tests, I’ve found the Bauer’s motor seems more robust and handles extended cutting sessions better, though Ryobi’s warranty and more widespread availability of parts give it some advantages.

The bottom line: Bauer offers exceptional value in its price category, delivering performance that rivals more expensive brands while maintaining affordability. It’s not the absolute best band saw on the market, but it likely offers the best performance-to-price ratio for casual to moderate users.

The Technical Details: Blade Specifications

Understanding blade compatibility is crucial for getting the most from your band saw. The Bauer accepts standard 67-inch band saw blades, which are widely available from various manufacturers.

Blade width can range from 1/8-inch for tight curve cutting to 3/8-inch for straight cuts and resawing operations. The standard blade that comes with the saw is typically a 3/8-inch, 6 TPI general-purpose blade suitable for most wood cutting tasks.

When shopping for replacement blades, you’ll encounter various tooth configurations:

- Standard/Regular tooth: Evenly spaced teeth, good for general cutting

- Skip tooth: Widely spaced teeth that excel at cutting thick stock and preventing sawdust buildup

- Hook tooth: Aggressive cutting angle, ideal for fast ripping in softwoods

- Variable pitch: Teeth with varying spacing that reduce vibration and provide smoother cuts

For most hobbyist applications, I recommend having at least three blades on hand:

- A 1/4-inch skip tooth for general purpose cutting and moderate curves

- A 1/8-inch regular tooth for tight curves and detailed work

- A 3/8-inch hook tooth for resawing and straight cuts in thicker stock

Quality matters with band saw blades. In my experience, investing in premium blades from manufacturers like Starrett, Lenox, or Olson results in cleaner cuts and longer blade life, even when used on an economical saw like the Bauer.

Blade Replacement: Easier Than You Might Think

Changing blades on the Bauer band saw is straightforward, though it can seem intimidating to newcomers. Here’s the process I’ve found works best:

- Unplug the saw for safety (always your first step!)

- Loosen the blade tension by turning the tension knob on top of the saw counterclockwise

- Open both the upper and lower wheel covers by turning their respective knobs

- Remove the table insert and loosen the table adjustment knob

- Carefully slide the current blade off the wheels and out through the slot in the table

- Install the new blade, making sure the teeth are pointing downward toward the table

- Center the blade on both wheels and begin tensioning slightly

- Adjust the blade guides and thrust bearings to properly support the new blade

- Fully tension the blade according to its width (wider blades need more tension)

- Close all covers, reinsert the table insert, and you’re ready to go

The first few times I changed blades, it took about 15 minutes. With practice, I can now complete the entire process in under 5 minutes. The Bauer’s design makes blade changes relatively painless compared to some other models I’ve used.

One tip I’ve found helpful: keep a dedicated 5mm Allen wrench nearby specifically for blade changes. Having the right tool readily available makes the process much more convenient.

What’s in the Box: Included Accessories

The Bauer band saw comes with a basic but functional set of accessories. Standard inclusions are:

- The band saw unit itself

- A cast iron work table with tilt capability

- One general-purpose wood cutting blade (typically 3/8-inch, 6 TPI)

- A miter gauge for angled cuts

- Basic setup tools (Allen wrenches)

- Owner’s manual with setup instructions

Notably absent are items like a rip fence, work light, or dust collection port adapters. These are available as separate purchases or aftermarket additions. I’ve found that adding a simple LED clamp light and fashioning a DIY dust collection adapter significantly improves the working experience.

The included miter gauge is functional but basic. If precision angled cuts are important for your work, you might consider upgrading to an aftermarket miter gauge with more robust construction and finer adjustment capabilities.

Power and Performance: What to Expect

With its 10-amp motor, the Bauer band saw delivers approximately 3/4 horsepower—sufficient for most hobbyist and light professional applications. This power rating allows it to cut through 3-4 inch hardwoods without bogging down, though I’ve found that slower feed rates yield better results in denser materials.

The saw operates at a fixed speed of approximately 2,500 feet per minute (FPM). Unlike some higher-end models, the Bauer doesn’t offer variable speed control. This fixed speed works well for most wood cutting applications but can be limiting when working with metals or certain plastics that benefit from slower blade speeds.

A workaround I’ve used for materials requiring slower speeds is to install a router speed controller between the outlet and the saw. This external device allows you to reduce power to the motor, effectively lowering the blade speed. It’s not an ideal solution, as it reduces torque along with speed, but it can work for occasional metal cutting needs.

In terms of cut quality, the Bauer produces surprisingly clean cuts with the right blade installed. Drift (the tendency of the blade to wander from the intended cut line) is minimal with proper setup and blade tension.

Professional Tool or DIY Solution?

One of the most common questions about the Bauer band saw concerns its suitability for professional use versus DIY applications. After extensive use, my assessment is that it occupies a middle ground that leans toward the DIY end of the spectrum.

For professional woodworkers who use a band saw daily for extended periods, the Bauer may not offer the durability and feature set required. The fixed speed, moderately sized work table, and component quality are designed for intermittent rather than continuous use.

However, for professionals who need a band saw only occasionally, or for those running small craft businesses with moderate production demands, the Bauer represents an excellent value proposition. I know several small-batch furniture makers and artisans who use the Bauer as a secondary or backup saw with good results.

Where the Bauer truly shines is in the serious DIY and hobbyist space. Weekend warriors, home improvement enthusiasts, and hobby woodworkers will find it more than capable of handling typical projects. Its balance of affordability and performance makes it particularly suitable for those transitioning from casual to more serious woodworking.

Metal and Pipe Cutting Capabilities

While primarily designed for woodworking, the Bauer band saw can certainly handle metal cutting tasks with the appropriate blade installed. I’ve successfully cut:

- Aluminum profiles up to 1/2 inch thick

- Brass and copper stock

- Mild steel up to 1/4 inch thick

- Various pipes and tubing in both plastic and metal

For cutting metal, I recommend using bi-metal blades with 14-24 TPI, depending on the material thickness and desired finish quality. The higher tooth count provides cleaner cuts in metal but requires a slower feed rate to prevent overheating.

When cutting pipes or tubing, use a V-block or similar support to prevent the material from spinning or collapsing under pressure. I fashioned a simple V-block from scrap hardwood that works perfectly for this purpose.

One limitation to be aware of: the fixed speed of the Bauer is faster than ideal for most metal cutting applications. Professional metal-cutting band saws typically run at much lower speeds (around 100-300 FPM compared to the Bauer’s 2,500 FPM). This higher speed means you’ll need to:

- Use a very slow feed rate

- Take breaks to prevent blade overheating

- Accept that blade life will be shortened when cutting harder metals

Despite these limitations, I’ve found the metal cutting performance adequate for occasional needs. If your projects frequently involve metal cutting, however, you might want to consider a dedicated metal-cutting saw or a higher-end dual-purpose model with variable speed control.

Speed Settings: A Fixed Proposition

As mentioned earlier, the Bauer band saw operates at a fixed speed of approximately 2,500 FPM. This single-speed design simplifies the tool’s construction and helps keep costs down, but it does limit versatility for certain applications.

The fixed speed is well-suited for:

- Most woodworking applications

- Cutting plastic materials

- Some non-ferrous metals when using appropriate blades

It’s less ideal for:

- Ferrous metals that benefit from slower speeds

- Very dense hardwoods where slower speeds might prevent burning

- Delicate materials requiring precise control

For those familiar with variable-speed band saws, this limitation might seem significant. In practice, however, I’ve found that feed rate control (how quickly you push the material through the blade) compensates for much of this limitation. By slowing your feed rate and using appropriate blades, you can successfully work with most materials despite the fixed speed.

If variable speed control is essential for your work, you’ll need to look at higher-end models like the JET or Grizzly band saws, which typically start at $500 and up.

Warranty and Customer Support

The Bauer band saw comes with Harbor Freight’s standard 90-day warranty. This is admittedly shorter than the 1-3 year warranties offered by premium brands, reflecting the tool’s budget-friendly positioning.

For additional peace of mind, Harbor Freight offers extended protection plans at reasonable rates (typically around $20-30 for 1-2 years of additional coverage). I generally recommend these plans for power tools in this price range, as they provide good value relative to the initial investment.

In terms of customer support, Harbor Freight has improved significantly in recent years. Their in-store associates are generally knowledgeable about the products they sell, and phone support is available for technical questions. Replacement parts can be ordered directly through Harbor Freight, though availability can sometimes be spotty for less common components.

One advantage of the Bauer’s relatively straightforward design is that many parts are standard components that can be sourced from industrial supply companies if needed. I’ve replaced guide bearings with standard sealed bearings from a local supplier when I couldn’t wait for official replacement parts.

Portability: Workshop Fixture or Job Site Tool?

At approximately 60 pounds, the Bauer band saw is relatively portable for a stationary power tool but not something you’d want to frequently transport. It falls into what I’d call the “occasionally movable” category—suitable for relocating within a workshop or transporting to different work locations infrequently.

The saw’s footprint is compact enough to fit in most workspaces, requiring roughly a 20″ x 20″ area plus room for operator positioning. I’ve found it works well on a dedicated stand, but it can also be mounted to a workbench or even used on a sturdy folding table when space is at a premium.

For those who need true portability, compact portable band saws (sometimes called band saw cutters) might be more appropriate. These handheld tools sacrifice cutting capacity and precision for mobility. The Bauer line includes portable models as well, which complement rather than replace the stationary version.

In my setup, I have the band saw mounted on a rolling stand that allows me to position it where needed, then tuck it against the wall when not in use. This compromise between portability and stability has worked well for my mixed-use workshop.

Replacement Blades: Availability and Options

One advantage of the Bauer band saw’s standard 67-inch blade size is the wide availability of replacement options. Unlike some tools that require proprietary consumables, the Bauer accepts standard blades available from numerous manufacturers.

Quality replacement blades can be found at:

- Woodworking specialty stores

- Online retailers like Amazon, Rockler, or Woodcraft

- Industrial supply companies

- Even some well-stocked hardware stores

Brand options include Olson, Starrett, Timber Wolf, Lenox, and Harbor Freight’s own Warrior line, spanning a wide range of quality and price points. Premium blades typically cost $15-25 each, while budget options can be found for under $10.

I’ve tried numerous blade brands and found that mid-range options like Olson and Timber Wolf offer the best balance of performance and value for most applications. The premium Starrett blades last noticeably longer when cutting harder materials but come with a price premium that may not be justified for occasional users.

Harbor Freight’s own replacement blades are serviceable for general woodworking but tend to dull faster than higher-quality alternatives. I keep a few on hand for rough cutting or potentially blade-damaging operations where I wouldn’t want to risk an expensive blade.

Maintenance: Keeping Your Saw Running Smoothly

Proper maintenance dramatically extends the life of any power tool, and the Bauer band saw is no exception. My routine maintenance schedule includes:

After Each Use

- Clear sawdust and debris from the table and blade guides

- Wipe down exposed metal surfaces to prevent rust

- Release blade tension if the saw won’t be used for several days (reduces strain on the wheels and blade)

Monthly Maintenance

- Check alignment of wheels and adjust if necessary

- Inspect guide bearings for smooth rotation

- Clean accumulated sawdust from inside the cabinet

- Lubricate moving parts with a light machine oil

- Wax the table surface for smoother workpiece movement

Quarterly Maintenance

- Check drive belt condition and tension

- Inspect electrical cord and switch for damage

- Thoroughly clean wheel tires and check for wear

- Verify blade tracking and guide alignment

- Check motor brushes if accessible

One maintenance tip that’s served me well: keep a small brush dedicated to clearing sawdust from hard-to-reach areas around the blade guides and wheel housings. I use a modified paintbrush with the handle shortened for better maneuverability in tight spaces.

For rust prevention on cast iron components, I apply a thin coat of paste wax after thorough cleaning. This creates a protective barrier against moisture while maintaining a smooth working surface. Just be careful to keep wax off the rubber wheel tires, as it can cause slipping.

User Reviews and Community Feedback

The Bauer band saw has garnered a substantial following among budget-conscious woodworkers and DIY enthusiasts. Browsing through online forums, social media groups, and Harbor Freight’s own review section reveals a generally positive consensus with some consistent themes.

Positive feedback frequently mentions:

- Excellent value for the price point

- Surprising cutting capacity for a compact saw

- Adequate power for most hobbyist applications

- Decent build quality compared to other budget options

- Good compatibility with standard accessories and blades

Common criticisms include:

- Limited table size for larger workpieces

- Basic fence and miter gauge quality

- Occasional alignment issues requiring adjustment

- Single speed limitation for versatility

- Short warranty period

The overall rating typically hovers around 4 out of 5 stars across various platforms, which aligns with my own assessment. It’s not a perfect tool, but it delivers impressive performance for its price category.

I’ve noticed that many reviewers who initially purchased the Bauer as a “starter” band saw end up keeping it even after they could afford to upgrade. This speaks to its capability as more than just an entry-level option.

Beginner-Friendly Features

For those new to band saws, the Bauer offers several features that make it particularly accessible:

- Straightforward setup with clear instructions

- Simple blade tensioning system with visual indicators

- Tool-less blade guide adjustment for quick changes

- Stable base that reduces vibration and improves cutting accuracy

- Smooth-operating table tilt mechanism

- Clear blade tracking window to monitor performance

The learning curve is relatively gentle compared to some more complex tools. I’ve introduced several woodworking newcomers to band saw operation using the Bauer, and most were making successful cuts within minutes.

One beginner-friendly aspect I appreciate is the visible blade tracking mechanism, which makes it easy to understand how blade alignment affects performance. This transparency helps new users develop good habits from the start rather than struggling with hidden adjustment points.

The only area where beginners might need additional guidance is in blade selection and replacement. The included manual covers the basics, but I recommend watching a few online tutorials specifically about band saw blade changing to build confidence before attempting it for the first time.

Conclusion: The Final Cut

After spending considerable time with the Bauer band saw, cutting everything from delicate scrollwork to hardwood resawing projects, I’ve developed a clear picture of its strengths and limitations. This understanding allows me to confidently recommend it for specific users while steering others toward alternatives that might better suit their needs.

The Bauer band saw excels as a value-oriented tool that delivers impressive performance without breaking the bank. It occupies that sweet spot between bargain-basement options that frustrate with their limitations and premium models that offer features many users rarely need.

For hobbyists, DIY enthusiasts, and woodworkers on a budget, the Bauer band saw represents an exceptional value proposition. It allows you to tackle a wide range of projects with good results while leaving more of your budget available for materials, other tools, or specialized accessories.

Professional users with demanding production schedules might find its limitations more significant, particularly the fixed speed and modest table size. For them, it might serve well as a secondary or backup tool rather than a primary workhorse.

What continues to impress me most about this saw is how it democratizes woodworking techniques that once required much more expensive equipment. Procedures like resawing, curve cutting, and template work are now accessible at a price point that would have been unthinkable just a decade ago.

If you’re looking to add band saw capabilities to your workshop without a major investment, the Bauer deserves serious consideration. It might not be the last band saw you’ll ever need, but it will certainly enable you to build skills and create impressive projects while you decide if a premium upgrade is warranted for your specific needs.

In the workshop, as in life, the right tool isn’t always the most expensive one—it’s the one that helps you accomplish your goals within your means. By that definition, the Bauer band saw is undoubtedly the right tool for many makers.